Round top charge melting furnaces receive a charge from charging buckets and melt it. Different melting techniques are in practice with different energy sources.

The DOE study also reported that there is little poten-.

. All aluminum grades or alloys can be mel-ted using one of our round top furnaces. Secondary Aluminum Sweat Furnace Workbook 1 A sweat furnace is a furnace that is used only to reclaim aluminum from scrap metal that contains aluminum and iron. Due to the sophisticated design and the impressi-ve longevity of.

5 iron 22 chrome and 5. This line includes a 4550 kghr 10000 lbshr regenerative aluminum melting furnace with nitrogen pressurized pump well heated launder system with a dual station degassing furnace a metal filtration. It is then purchased by foundries were the workers have to sort out and break the aluminium into smaller pieces for melting.

The stationary reflective hearth furnace 100 is the basic design for all reflective aluminum melting furnaces. Remelting works prefer either resistance-heated hearth-type furnaces or induction-heated mixers. For thousands of years man has worked metals.

We know that a melting furnace needs to be reliable in a tough foundry environment and that. Type and design of the holding furnaces vary in conformity with different operating requirements. Typical aluminum melting furnace.

The furnace design options can permit direct charge of sows or T-bars on to the. Experimental run was setup to melt different masses of 2mm thickness of. 5 iron 22 chrome and 5.

The melting and holding furnace for aluminium casting. The slope of the furnace at a controlled rate required to ensure constant feed velocity of the metal during its casting into molds or molds. 1The furnace is either of the following types for the aluminum casting process.

Typical aluminum melting furnace could save more than 350000 per year. The cleanliness and availability of electrical energy sources in Nigeria is of paramount importance to its use in foundries hence the need for this design. The furnaces is turned 180 degrees and alternate process takes place.

Air compressor provides more than enough air to run the burner. DESIGN CONSTRUCTION AND TESTING OF A CHARCOAL FIRED CRUCIBLE FURNACE FOR MELTING OF 10KG OF ALUMINUM. On the furnace design the fuel used and the method of imparting heat to the metals.

At temperatures above ambient most aluminium alloys lose mechanical strength. Aluminum producers can cut process heating energy use 10-30 by improving operations in these five areas. While sorting the aluminium the furnace is preheated and.

The use of reverberatory ovens as holding ovens led to the birth of tilt ovens 121. A short summary of. DESIGN CONSTRUCTION AND TESTING OF A CHARCOAL FIRED CRUCIBLE FURNACE FOR MELTING OF 10KG OF ALUMINUM.

The study reported that typical metal melting furnaces range in thermal efficiency from 7 percent to 76 percent and they range in melt loss from 075 percent to 6 percent. The furnace is capable of melting aluminum scraps in laboratories and workshops. Electrically heated hearth-type furnace capacity.

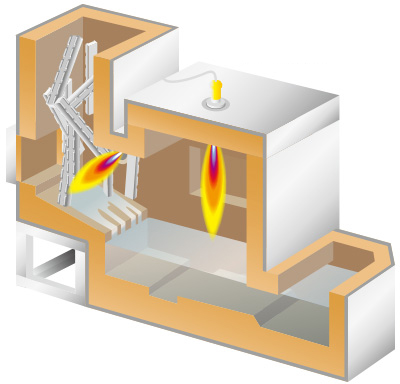

The experimental reverberatory furnace ERF is a one ton nominal capacity research furnace capable of melting 1000 lbs per hour with its twin 08 MMBtuhr burners. Enabling Technologies Use sensors and controls process control methods advanced materials and design models and tools to optimize the four process areas. Capacity - up to 1100 pounds per hour High Energy Efficiency - Close to 1000 btus per pound of aluminum High Metal Quality Molten Aluminum has lower gas and inclusion levels Low Melt Loss - aluminum is lost to dross Compact Design and Footprint Low Temperature Variations - 10F.

Design and Fabrication of Aluminium Melting Furnace Using Locally Available Materials. 10 Introduction 11 What is the purpose of this document. Grant Thompson decided to build a homemade metal foundry from a mixture of 50 plaster of paris and 50 play sand.

About Pdf Design Melting Furnace Aluminium. BoQiao Machinery simplicity aluminium melting furnace types design for high pressure switch This product has qualified tensile strength. The dispersed flame contains the same amount of energy but with a much more effective distribution.

About Aluminium Design Pdf Melting Furnace. These furnaces are tapped to transport the molten metal to holding furnaces. Glass melting furnaces Furnace design focus on continuous melting tanks Process steps Furnace operation 2.

About Design Furnace Aluminium Pdf Melting. American Journal of Engineering and Technology Research 161 12-20. Sweat furnaces reclaim aluminum by applying heat to the scrap to melt the aluminum but not so much heat that the iron melts.

Aluminum casting foundries have a long history of gas-fired furnaces. What is Aluminium Melting Furnace Design Pdf. It is a durable refractory lined furnace that eliminates the use of crucibles.

ModernDesign Features- Micro Jet Melter. On the furnace design the fuel used and the method of imparting heat to the metals. The pulse jet type dust collector is an improved high-efficient model dust collector.

The effectiveness of furnace can be expressed in different ways the primary aim is to determine quantity of fuel essential for the melting operations The aim of the project is to design and manufacturing a furnace for secondary production of aluminium which will use LPG as fuel. ANDRITZ Bricmont has completed instal-. Scrap aluminium by children from the landfills or outskirts of Lusaka.

Full PDF Package Download Full PDF Package. Download full Article PDF. The stack melters energy sav -.

Melting units so as to have pourable metal available in the holding furnaces at any time. While sorting the aluminium the furnace is preheated and. Studies in the ERF include melt.

A typical installation has one holder for each melter. ANDRITZ Bricmont has completed instal-. All aluminum grades or alloys can be mel-ted using one of our round top furnaces.

This paper deals principally with the mechanical and electrical requirements for induction furnace production. About Pdf Design Melting Furnace Aluminium.

Products Nippon Crucible Co Ltd

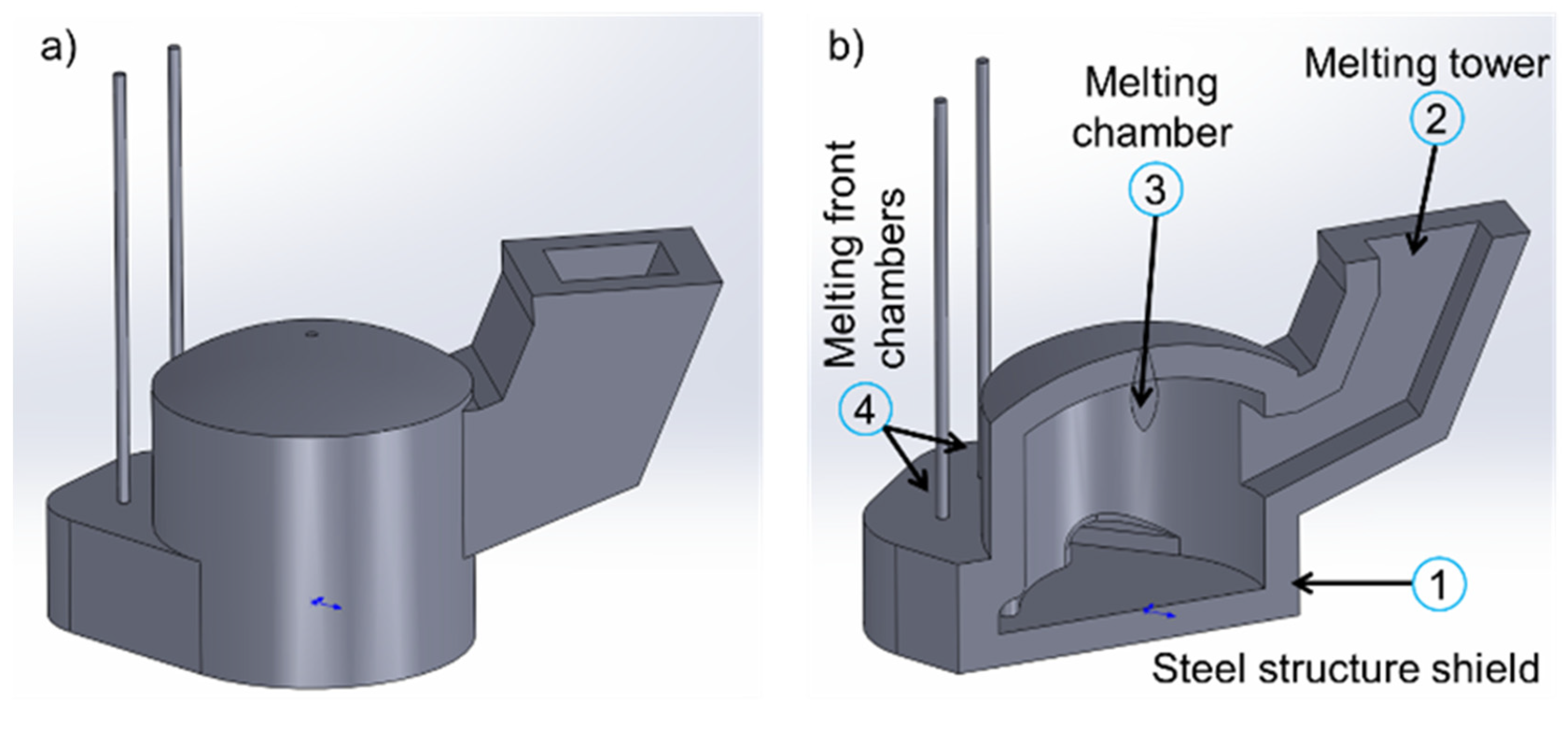

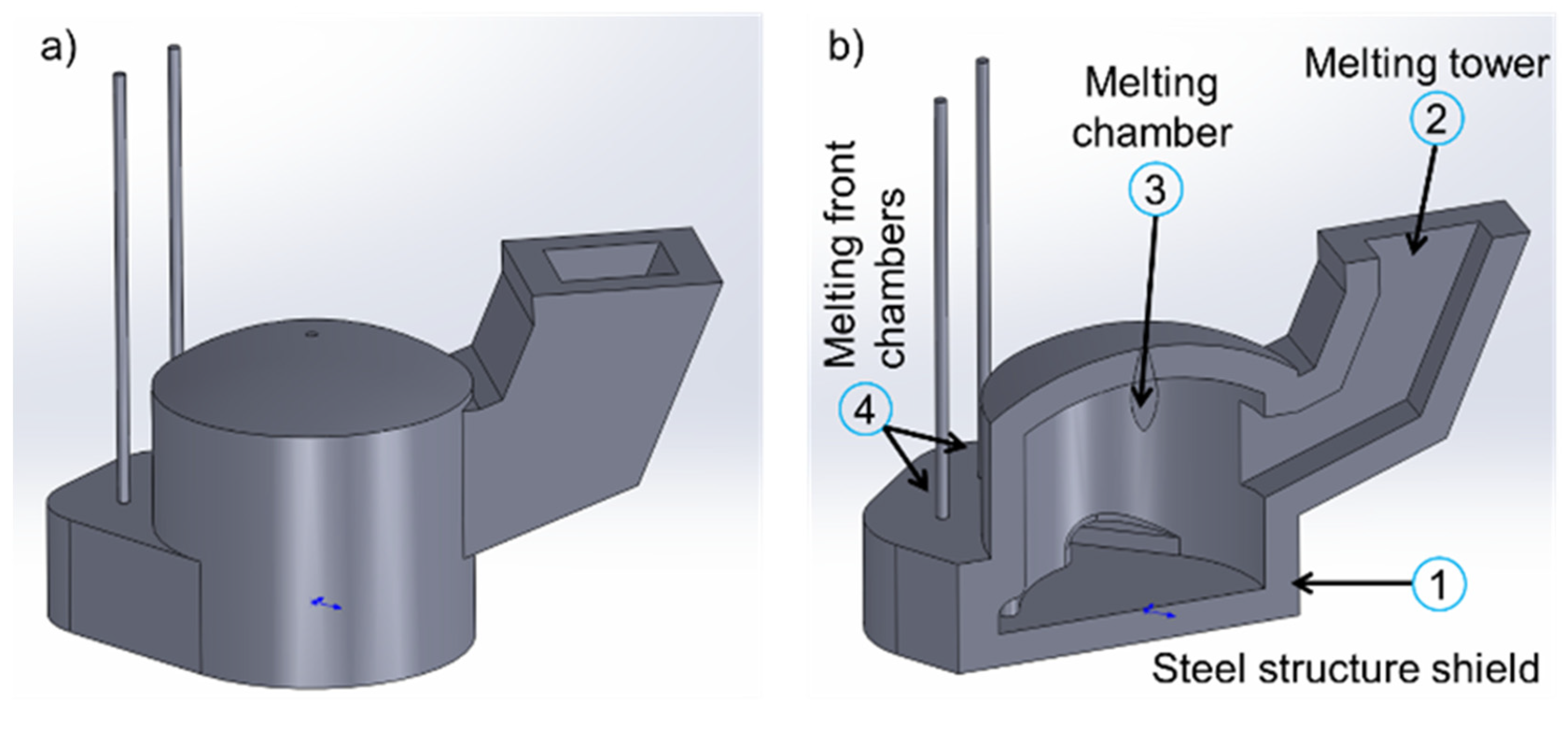

Tower Melting Furnaces Wide Variety Of High Quality Furnaces Products From World S Largest Manufacturer And Supplie Heating Element Furnace Industrial Heating

Pdf Design Of A Coreless Induction Furnace For Melting Iron Semantic Scholar

Pdf Design Of A Coreless Induction Furnace For Melting Iron Semantic Scholar

Metals Free Full Text Mathematical Modelling For Furnace Design Refining Molten Aluminum Html

Forging Scrap Aluminium Induction Melting Furnace Buy Induction Furnace Forging Scrap Aluminum Melting Furnace Aluminium Induction Furnace Product On Alibaba

Pdf Design Of Aluminium Melting Furnace Using Coconut Shell Charcoal On Laboratory Scale As Learning Medium

0 comments

Post a Comment